In the Collins Research Group, we are …

Stories in brief:

Writing in Composition: Research in Additive Manufacturing generally makes the assumption that the composition of the part will be the composition of the powder used. This project firstly showed that electron beam melted Ti-6Al-4V experiences preferential vaporization of aluminum during the melting of powder, influenced by the scanning strategies (point vs. linear raster). The second stage of the project exploited this behavior to “write in” the composition, i.e., have specific composition in specific locations in an AM EBM Ti-64 sample by changing the scanning strategy at specific locations. Besides composition, by changing the scanning strategy the material shows different properties between locations, such as hardness, microstructure (colony-basketweave), presence of defects, mechanical properties, oxidation, among others.

Spatially Resolved Acoustic Spectroscopy: We are the only research group outside of the UK to have a functioning SRAS system. In collaboration and consultation with the University of Nottingham, we have developed the sensors, optics strategies, mechatronics, and other physical hardware, software, and data handling strategies to enable this new type of microscope. We have integrated our SRAS system into the workflow of a Robo-Met.3D serially polishing system, and are collecting our first 3D SRAS datasets. We are building our second SRAS microscope – a gantry style microscope with a larger scan area, and making use of some lower powered lasers. The gantry style system will permit us to explore a range of new techniques, lasers, and optics, as the parts and system are more easily interchangeable. Using the SRAS microscopes, we plan on tacking several complex problems facing the materials science communities, as well as those agencies and industries that use advanced materials. We can collect very large area orientation microscopy datasets (>10s of square inches) to understand texture in additively manufactured materials. We intend to use this instrument to support research into studying and quantifying microtextured regions in titanium alloys, and have a few other fun broader scientific problems we will explore (after all, SRAS isn’t just for metals).

Using Defects as ‘Microstructural Informants’: In structural engineering applications, porosity is typically a defect that leads to reduced properties and performance, and in extreme cases, can result in engineering failures and loss of systems, infrastructure, or life. While recognizing that pores need to be eliminated, we are also looking at porosity in new ways. Their presence permits them to serve as “microstructural informants” (or fossils) to help us understand physics at length and time scales not typically accessible.

In our early work, we have identified that spherical gas pores can undergo microscopic buckling, helping us to interpret the gradients of temperature and stress that surrounded the pores prior to their buckling. As importantly, we have discovered that these are invariably linked with local compositional fluctuations, consistent with a theory that the pores are carried by density-driven convection.

Predicting Properties in Titanium Alloys: We have used machine learning, artificial intelligence, and various hybrid strategies to predict properties in titanium alloys. Our goal is to develop physically-based constitutive equations so that we can relate inputs associated with the materials state (e.g., composition, microstructure) to the properties in a way that is process-agnostic. In this way, an equation developed for one additive manufacturing approach is just as applicable to forged product or another additive manufacturing approach. We have demonstrated this and are able to predict uniaxial tensile properties for Ti-6Al-4V, including yield strength, ultimate tensile strength, and full stress-strain curves. Our models can be easily integrated into statistically-based modeling approaches to predict ‘design allowable’ curves for practicing engineers. We have made inroads into understanding fracture toughness, and have used our approaches to predict properties of alloys that are not Ti-6Al-4V, and are currently working on beta Ti-based alloys.

Combinatorial Studies: We have two ways of conducting combinatorial studies. We can firstly use additive manufacturing to change the composition of materials along a single direction, and assess directly the influence of composition on microstructure and mechanical properties. We have also demonstrated that we can induce a thermal gradient orthogonal to a composition gradient, and explore large sections of a binary phase diagram in a single specimen.

Precession Electron Diffraction (PED): At the other end of the characterization length scale to map orientation is a transmission electron microscope (TEM) technique known as precession electron diffraction. We have incorporated methods to use local differences in the crystal orientation to extract out (and spatially map) dislocation densities. We have also measured grain boundary character distributions (GBCDs) of nano crystalline materials, measuring grain boundaries of more than 50,000 grains. We are looking towards conducting 3D reconstructions of the reciprocal lattice using this technique, as well as improving our measurements and resolution of our dislocation density maps.

Between PED, conventional SEM-based orientation microscopy using EBSD, and our SRAS capabilities, we are the only group capable of conducting orientation microscopy from 2nm resolution steps to 20,000 square millimeter areas mapped.

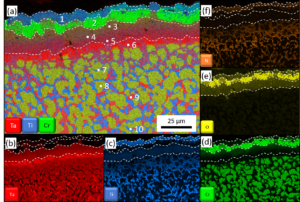

RCCA’s: Refractory complex concentrated alloys (a.k.a. RCCAs) are an emerging class of alloys that show great potential for advanced aerospace applications. We have investigated the effects of composition, microstructure, and surface modifaction on the complex oxidation mechanisms observed in these alloys, especially at elevated temperatures (>1000°C). Understanding the nuance and complexities that govern these processes and the deviations from conventional alloy behavior will ideally allow for the acceleration of development of RCCAs into the commercial space and industrial scale.

DEPSCoR: We are looking into the relationships between processing, microstructure, and properties of additively manufactured duplex stainless steels (DSS) using laser-powder directed energy deposition (LP-DED) and wire and arc additive manufacturing (WAAM). From this characterization, our goal is to create constitutive equations that can predict the tensile properties of DSS using its materials state. We are also using this data to determine a method to create parts with self-similar microstructures using LP-DED and WAAM to promote research into hybrid additive manufacturing to increase throughput for additively manufactured materials.

Watch this space: While we can’t put everything that we do on the website, we have a few other projects that are at various stages of development. These include:

* Fracture in advanced nonferrous structural alloys, including crack propagation and branching in titanium and aluminum alloys

* Quantifying, characterizing, and locating defects, including challenging problems associated with new techniques for dislocation density quantification, new techniques for resolving porosity levels better than 1%, and the nature of the chemistry within pores.

* In-situ characterization of physics associated with powder-blown directed energy deposition using beam lines.