Funding

Thanks to the following agencies for supporting our research!

Department of Defense (DOD), Army Research Office (ARO), Defense Advanced Research Projects Agency (DARPA), Air Force Office of Scientific Research (AFOSR), Army Research Lab (ARL), National Aeronautics and Space Administration (NASA), National Science Foundation (NSF), Nuclear Energy University Program (NEUP), Los Alamos National Laboratory (LEEG) funding, NEVADA NASA EPSCoR, IOWA NASA EPSCoR, NEVADA NASA Space Grant Consortium, IOWA Space Grant Consortium, ThinkSwiss, NAASIC (University of Nevada, Reno), Nevada EPSCoR.

About Our Research

Our Group is interested in the quantitative and qualitative measurement of materials behavior at lower(micron to sub-micron to nanometer) length scales over various material systems. Our research is focused on these main areas:

- Mechanistic Design of multilayered components

- Materials under extremes

Current Research Projects

|

|

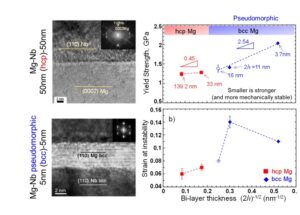

Understanding Pseudomorphic Phase Transformations in Multilayered Nanocomposites

Project Member: Dr. Kevin Jacob Funding agencies: NSF-Faculty Early Career Development Program (CAREER), Center for Integrated Nanotechnologies, Los Alamos National Laboratory This work explores the possibility of synthesizing a novel material system whose properties are dominated by a hitherto unstudied hexagonal close-packed (hcp) –body-centered cubic(bcc) interfaces. By refining the length scales to nanometer dimensions, and coupling orientations between the two phases, the final composite system is expected to have enhanced strength as well as ductility, in spite of the inherent low ductility of the Mg phase. Such nano-Mg-X alloys are postulated to enable significant increases in its ductility from that of conventional hcp Mg and the nanostructure is expected to bring about an order of magnitude increase in strength while retaining the lightweightness (high strength-to-weight ratio) of elemental Mg. We utilize a combination of indentation testing and in-situ SEM (scanning electron microscope) micro-pillar compression experiments to study the deformation. Measuring ductility using micro-scale fracture toughness testing using a 3-point bend geometry. |

||

|

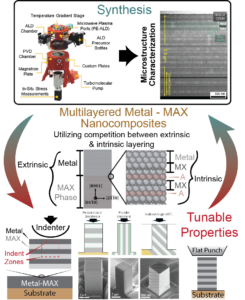

Project overview schematic illustrating how synthesis will use the competition between extrinsic and intrinsic layer mechanisms to leverage tunable properties characterized through nanomechanical techniques.

|

Engineering Multilayered Metal-MAX phase Nanolaminate materials for tunable strength and toughness Project member: Skye Supakul Collaborators: Dr. Garritt Tucker, Baylor University Funding Agency: Army Research Office (ARO – W911NF1910389, Program Manager: Dr. Daniel P. Cole) This project utilizes an integrated experimental (Iowa State University) and computational (Dr. Garritt Tucker, Baylor University) effort funded by the Army Research Office to engineer multi-layered nanocomposite materials with unprecedented tunable strength and toughness. The nanocomposite is composed of alternating layers of metallic and MAX phase layers with lamellar thickness reduced to the nanoscale. Unique to other multi-layered systems, the metal-MAX architecture detailed here is composed of a hierarchical topology with interfaces between the layers in direct competition with internal atomistic interfaces within the MAX layer to drive enhanced macroscopic mechanical behavior. Experimental synthesis and novel nanomechanical testing (i.e. nanoindentation and micropillar compression) performed at Iowa State University will look to quantify and qualify material properties and behaviors, providing experimental feedback for computational modeling and simulations developed by collaborators at the Baylor University investigating the interfacial structures and stability to elucidate the relationship between the hierarchical structure and improved mechanical properties.

|

|

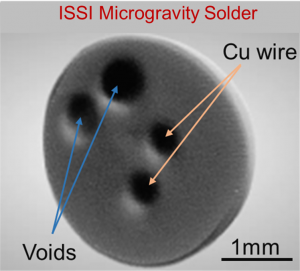

Structure and Properties of Microgravity and Terrestrial Solders under Extremes of Elevated and Cryo temperatures Project member: Manish Kumar Collaborators: NASA, Tec-Masters, Inc. Funding Agency: NASA PSI, NASA EPSCoR We have been awarded NASA PSI and NASA EPSCoR International Space Station (ISS) Flight Opportunity grant for “Structure and Properties of the Solder Joints Produced in Microgravity and Terrestrial environments.” This is collaborative work between the PI team at ISU, NASA researchers, and ISS implementation partners (Tec-Masters, Inc.). This study compares solders prepared in terrestrial vs. microgravity (aboard the International Space Station, ISS) environments, 1g vs. ~1×10-5g. Using Pb-Sn solders from the In-Space Soldering Investigation (ISSI), we demonstrate how the lack of Earth’s natural convective flow and buoyancy effects during melting/solidification onboard ISS affects its microstructure and Properties, and performance. The understanding gained in this study will enable robust and reliable protocols for soldering-based solutions to address repair and fabrication needs for long-duration human exploration missions in (and beyond) low Earth orbit (ex: Moon, Mars). This project also studies the reliability of the solder joints under the extremely elevated and cryo temperatures experienced during the moon (-230 oC to +120 oC) and Mars (-120 oC to +25 oC) rover missions, which will have a high impact on the success of future deep space exploration.

|

||||||

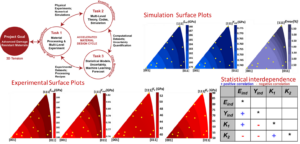

The flow of information between the four tasks to cyclically refine the design of damage-resistant material. The proposed work combines discovery and material design elements to achieve the project goal. |

Grain Interface Functional Design to Create Damage Resistance in Polycrystalline Metallic Materials

Project member: Olajesu Olanrewaju Collaborators: Dr. Curt Bronkhorst, Dr. Nan Chen (University of Wisconsin, Madison), and Dr. Marko Knezevic (University of New Hampshire ). Webpage: https://matstats.engr.wisc.edu Funding Agency: NSF DMREF (Award Number – 2118673, Program Manager: Dr. Siddiq Qidwai) This project aims to revolutionize material design and manufacturing by controlling defect/feature characteristics and internal stress states to achieve a 30% reduction in accumulated damage. Current limitations prevent the accurate prediction of when, where, or how metallic materials will fail under dynamic loading conditions relevant to the Air Force. This collaborative project focuses on quantifying the conditions for pore nucleation at grain boundaries, a critical defect/feature type. The objective is to develop damage and material design/manufacturing strategies under extreme loading conditions, including strain rates up to 104 s-1. Achieving this goal will involve innovative modeling, statistical analysis, uncertainty reduction, and computational simulations. These methods will be validated and verified through sample preparation, characterization, and testing at multiple length scales, with continuous feedback between these tasks. |

||||||

|

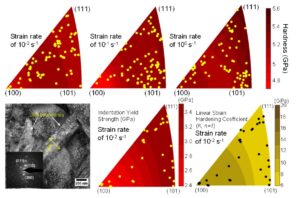

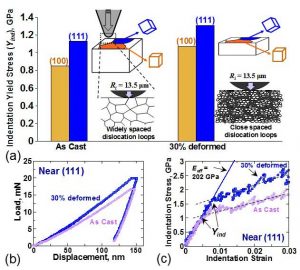

First row: Hardness as function of orientation at various strain rates. Second row: TEM of RHA steel, Indentation Yield Strength and Linear strain hardening coefficient at strain rate of 10-2 |

Center for Extreme Events in Structurally Evolving Materials

Project Members: Niraj Pramod Atale, Dr. Kevin Jacob, Ethan Shimak Collaborators: Dr. Curt Bronkhorst, Dr. Dan Thoma, Dr. Ramathasan Thevamran, Dr. Wenxiao Pan, Dr. Nan Chen (University of Wisconsin), Dr. John Borg (Marquette University), Dr. Amit Acharya (Carnegie Mellon University), Dr. Marko Knezevic (University of New Hampshire) Funding Agency: Army Research Office This study aims to deepen the understanding of rolled homogeneous armor (RHA) steel materials by validating methods to characterize local elastic-plastic damage properties of microscale constituents. The complex microstructural details, spanning from nanometers to micrometers, necessitate microstructure-property-performance correlations at various length scales. At ISU, small-scale testing techniques like high throughput nanoindentation, micro-pillar compression, micro-tensile, and notched micro-tension tests will be utilized. These tests, conducted under both quasi-static and dynamic modes, assess traditional properties and damage propagation. Mechanical data will correlate with structure information using XRD, HR-EBSD, SEM, and TEM techniques available at ISU and Ames Lab. Diverse testing methods allow detailed structure-property correlations at each scale, from individual interfaces to ensemble properties. Innovative experimental designs ensure high-throughput data collection. This comprehensive approach enables a thorough understanding of RHA steel behavior across multiple length scales.

|

||||||

|

Representative prototype prepared in collaboration with ISU vet school |

Biomaterial and Biomechanical Analysis of External Skeletal Fixators for Fracture Management in Small Animals Project Members: Amruta Vaghela Collaborators: Dr Karl Kraus, Iowa State University College of Veterinary Medicine This project focuses on designing a standardized external fixator system in small animals for orthopedic surgery applications. We propose to investigate the available materials systems and their corresponding mechanical responses in designing an external fixator system with optimal stiffness, strength and biocompatibility. External fixator surgery in small animals is a highly specialized procedure, as even slight variations in pin placement can lead to premature weakening or improper healing of the bone. Failure and fracture complications during surgery can turn into lifelong concerns for the patient, and in some cases may lead to euthanasia. The existence of a standardized method would allow surgeons to perform the procedure with a higher success rate and reduce the percentage of animals that must be euthanized for a curable condition. |

||||||

Completed Projects

|

Small-scale Characterization of the Additive Manufactured Functional Hierarchical Shape Memory Alloy Structures

Project member: Deeksha Kodangal Collaborators: Dr. Reginald Hamilton, Pennsylvania State University Funding Agency: DARPA This work focuses on the powder-fed AM technique- Laser Directed Energy Deposition (LDED) because of its inherent advantages when compared to the traditional route of producing Lamellar Shape Memory Alloy Structures (LSMAS). The AM LDED can be used for tailoring properties by controlling the elementally blended powder feedstock. The present work concentrates on understanding the anisotropy in the distribution in the precipitate morphology, grain texture and grain orientation along the LDED AM build height and build directions. The project aims to develop novel nano-/micro- scale test approaches that will establish the dependence of multi-scale deformation mechanisms on the differential microstructure length scales: precipitates and grains (nm-μm), AM layer/pass build plan (10-100 μm) and lamella of LSMAS (μm to mm). The interfaces between the build layers and between lamellae are in direct competition with the martensitic morphology and interactions with micro-constituents in the SMA to drive a tailored macroscopic mechanical behavior. |

|

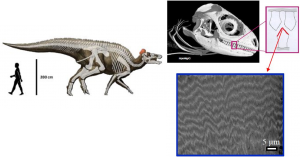

Biomechanics of Hierarchically-structured Hadrosaur Enamel in grinding dentitions Project member: Dr. Soumya Verma Collaborators: Dr. Brandon A Krick, Dr. Gregory M Erickson (Florida State University) Funding Agency: AFOSR, NSF This research aims to understand the biomechanical form, function, and structure of the enamel (a ceramic-like composite) known as aprismatic wavy enamel (WE) in the grinding dentition of large herbivores hadrosaurid dinosaurs. Our preliminary analysis of this tissue shows an undulating wavy structure in WE composed of folded layers of hydroxyapatite crystallites separated by thin layers of loosely aggregated interlayer matrix. This study specifically focuses on how the undulating wavy structure of this enamel helped dinosaurs’ teeth to deflect cracks and provided exceptional strength and toughness to mitigate the effects of fracture-promoting sediments while masticating.

|

|

|

Establishing processing-microstructure evolution linkages in polycrystalline metals

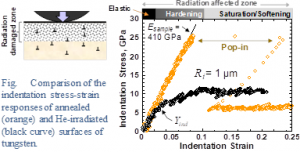

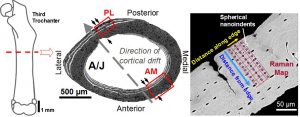

Our group’s research interests on nanomechanics addresses a critical need – that of deriving the precise relationships between microstructure and mechanical properties as the feature sizes of interest continue to decrease from micron to nanoscale dimensions. A major highlight is the development of novel data-analysis protocols for spherical nanoindentation, which allow meaningful spherical indentation stress-strain curves to be extracted from the raw datasets. This technique has now progressed into a field of its own where it is now possible to reliably estimate the entire indentation stress- strain response of a material at sub-micron length scales, starting from its initial elastic response and progressing all the way to its post-yield behavior. This enables coupling of the local mechanical response of a material, using spherical nanoindentation, with the structural information (see figure on left) obtained at the same length scale, thus paving the way for the successful development of physics-based multi-scale materials models at these lower dimensions. The versatility of this approach on a wide range of materials systems including metals, carbon nanotubes (CNTs), ceramics and biomaterials (bone) was published our 2015 invited review paper in Materials Science and Engineering: R.

Furthermore, these techniques are of special advantage in studies of extreme environments, such as the study of mechanical degradation of irradiated materials (Fig), where nanoindentation shows the greatest promise due to its non-destructive nature, ease of experimentation (only a polished surface prior to ion irradiation is needed), high throughput and versatility. Our 2013 DOE-NEET and 2019 DOE Nuclear Energy University Program fellowship grants on this topic aims to combine the information obtained from spherical nanoindentation with different indenter sizes with structure characterization methods (e.g. EBSD) and physics-based finite element simulations of indentations to arrive at reliable estimates of the local properties.

|

|

Mechanics and Materials Approach to Quantitative Assessment of Bone Quality

Beyond structural metals, our indentation stress-strain techniques have also enjoyed a fair degree of success in the study of micrometer and sub-micrometer sized domains in biological materials such as bone and enamel. Before the advent of such instrumented indentation methods, bone has been particularly challenging to characterize mechanically, especially at the micron length scales where the mineral and collagen components are closely intertwined. Our research in this field is aimed at to developing robust structure-property linkages in bone at each of its hierarchical levels of organization. Here we utilize tools such as quantitative backscattered electron microscopy (BSE-SEM), Fourier transform infra-red imaging (FTIR) and Raman vibrational spectroscopy to obtain the structure information at similar length scales. These projects will have the ambitious goal of assessing bone health and skeletal fragility, owing to age and disease related changes in the structure and morphology (quality and quantity) of bone, which is a growing problem in the United States and worldwide. More details: S. Pathak, J. Gregory Swadener, S. R. Kalidindi, H.-W. Courtland, K. J. Jepsen and H. M. Goldman,Journal of the Mechanical Behavior of Biomedical Materials,2011,4,34-43. S. Pathak, S. J. Vachhani, K. J. Jepsen, H. M. Goldman and S. R. Kalidindi,Journal of the Mechanical Behavior of Biomedical Materials,2012

|

|

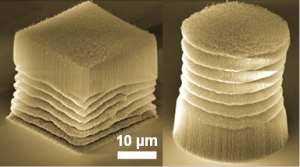

Collective Behavior of Vertically Aligned Carbon Nanotubes (VACNTs): from a Single Tube towards Complex Networks

In this work we explored the mechanical behavior of vertically aligned carbon nanotubes (VACNTs) also known as carbon nanotube (CNT) arrays, bundles, brushes, foams, forests, mats, and turfs. VACNTs are complex, hierarchical structures of intertwined tubes arrayed in a nominally vertical alignment due to their perpendicular growth from a stiff substrate. They are a unique class of materials having many of the desirable thermal, electrical, and mechanical properties of individual carbon nanotubes, while exhibiting these properties through the collective interaction of thousands of tubes on a macroscopic scale.

We investigated the synthesis techniques by which VACNTs are synthesized, which is the primary factor affecting their complex, hierarchical morphology. This microstructure, in turn, affects their mechanical behavior, in particular the modulus, buckling strength, and recoverability. Using nanomechanical testing techniques, we compared the mechanical response of VACNTs under different loading conditions, namely compression and indentation. We analyzed the resultant large variation in structure and properties of VACNTs (porosity, CNT tube thickness, modulus, buckling strength), their large scale deformation and buckling behavior, viscoelasticity and potential applications. https://link.springer.com/referenceworkentry/10.1007/978-90-481-9751-4_387 |